South Africa remains the cradle of the African automotive industry. With an industrial tradition spanning over a century, the country boasts a solid production base, recognized technical expertise, and a well-established network of equipment manufacturers. However, in an era of energy transition and the reconfiguration of global markets, South African industry must rise to the challenge of modernization.

- Large factories and major players

South Africa is home to the subsidiaries of most of the world’s automotive giants:

-

- Toyota (Durban / Prospecton): the country’s main factory in terms of volume, it assembles the Hilux and the Fortuner, vehicles that are very popular on the African and Australian markets.

- Volkswagen (Uitenhage): manufactures Polo models for Africa and Europe, with an annual production exceeding 160,000 units.

- Ford (Silverton, Pretoria): factory specializing in the production of the Ranger, exported massively.

- BMW and Mercedes-Benz (Rosslyn and East London): units producing high-end models, intended mainly for export.

These manufacturers rely on a dense industrial ecosystem, including hundreds of local and international subcontractors.

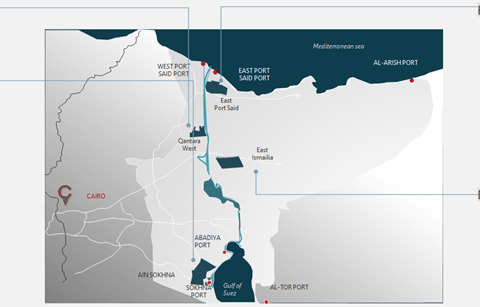

- Logistics infrastructure serving exports

Exports account for more than 60% of South Africa’s automotive production. This focus has led to sustained investment in infrastructure:

-

- Ports of Durban and Port Elizabeth: optimized for the export of vehicles and components, they ensure rapid links to Europe and Asia.

- Road and rail network: well developed around industrial centers, although modernization needs persist, particularly to streamline the transport of goods.

- The transition to electric

South Africa has launched its Green Transport Strategy aimed at:

-

- introduce the production of electric and hybrid vehicles on its production lines;

- stimulate domestic demand through tax incentives;

- invest in charging infrastructure and pilot projects (electric taxis, electric buses).

Ford and Mercedes-Benz have already announced investments to prepare their factories to produce electrified models for export.

- Challenges and ambitions

South African industry faces several challenges:

-

- Modernize its energy infrastructure to make factories more resilient to power outages (load shedding).

- Diversify its offering towards more environmentally friendly vehicles to remain competitive internationally.

- Strengthen local content and skills in new technologies (batteries, on-board electronics).

By 2035, South Africa aims to double its export volumes and become a key regional player in sustainable mobility.